DEVIPEEE project

2023 - in progress

Decontamination and Innovative Recycling of Brominated Plastics from WEEE

The DEVIPEEE project is a France 2030 project and aims to decontaminate plastics from WEEE (Waste Electrical and Electronic Equipment) to facilitate their recycling.

Some of these plastics are not recyclable under current regulations, as they contain levels of bromine and antimony in excess of authorized limits. These molecules come from brominated flame retardants and antimony oxides used in polymers to limit their flammability.

The challenges are to reduce the tonnages of plastics incinerated, increase the recovery rate of plastics and additives, and establish new business models.

EcoSCience project

2022 - in progress

Development of new analytical methods for more ecological environmental science

The main purpose of this project is to introduce a new analytical methodology using supercritical fluids, without compromising the quality of the data obtained. This is a “green” approach, as the use of supercritical CO2considerably reduces the consumption of organic solvents, which are toxic, polluting and costly. To achieve this, CEREGE is collaborating with the M2P2 laboratory (AMU) and IFS (Innovation Fluides Supercritiques), both of which specialize in the application of supercritical technologies. This multi-disciplinary and multi-sectoral project contributes to an effort to develop alternative, more environmentally-friendly analytical methodologies that will reduce our impact on the environment, while enabling us to gain a better understanding of climate evolution.

Video presentation of the project

SUPERPE project

2019 - 2023

Recycling household waste based on polyolefins

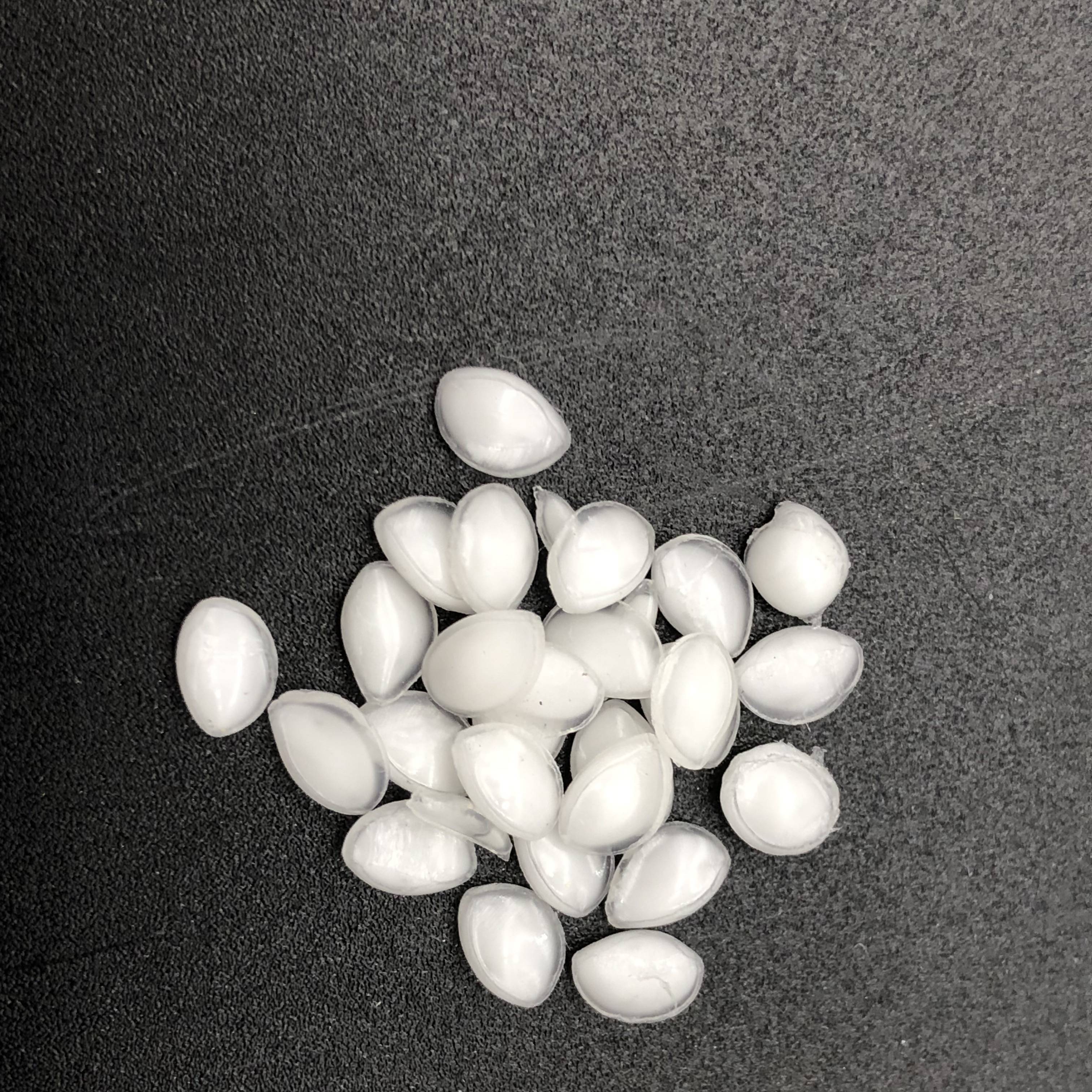

Thanks to a treatment process using supercritical CO2, the partners in the SuperPE project, supported by Citéo and coordinated by the Barbier Group, have demonstrated the possibility of decontaminating recycled polyethylene (PE) and polypropylene (PP) to levels compatible with the reintegration of these materials in new packaging suitable for food contact.

PE and PP alone account for more than 50% of the plastics used in food packaging, so it's vital that the plastics industry learns how to recycle them while guaranteeing a level of safety validated by the relevant authorities.

Decontamination levels of almost 100% have been achieved.

The SuperPE consortium has defined the operating conditions for batch decontamination using supercritical CO2. Based on measurement campaigns carried out on various post-consumer household waste deposits, model compounds representative of the identified contaminants were selected. Artificially contaminated compounds were used to challenge and optimize the efficiency of the supercritical CO2 decontamination process, on a batch scale of around 30 kilograms.

The results obtained are more than encouraging, since it has been shown that it is possible to decontaminate compounds with a molar mass of the order of 300 g/mol to a level of practically 100%. For compounds with higher molar masses, yields of the order of 90% have been achieved. In addition to the work carried out on compounds of controlled composition, tests on real post-consumer deposits have confirmed this ability to decontaminate over a wide range of molar masses.

SuperPE thus opens the way to an industrial process for the chemical decontamination of post-consumer PP and PE at a level of performance compatible with closed-loop recycling for food and cosmetics packaging.

SUPERMET project

2018 - 2021

Recovery and recycling of precious metals from used catalysts

The SUPERMET project proposes to explore a green, breakthrough technology for recycling precious metals, in particular palladium (Pd) and platinum (Pt), from used catalysts (e.g. petrochemical catalysts). The process is based on supercritical CO2 extraction using complexing polymers capable of transporting insoluble precious metals in the supercritical CO2 medium.

Precious metals are widely used in catalysis applications, not only in petrochemicals but also in the automotive industry (three-way catalyst) and in fine chemicals synthesis. The scarcity of these metals represents a risk for European countries that do not have access to this primary resource.

The pyrometallurgical and hydrometallurgical techniques currently developed to recover these metals are energy-intensive, destroy the treated materials and generate large volumes of toxic effluents. Thanks to the innovative recycling process proposed in this project, the catalytic support and precious metal remain intact and can be reused, along with the CO2 and polymer used, so there are no toxic effluents. Due to the adjustable solvent properties of supercritical CO2, the dissolved polymer-metal complex can be isolated from the CO2 by simple depressurization.